Introduction to new control software 4WB V2.0 (Jan. 2018 release)

Multi-lingual

Other than Japanese and English, Chinese and Korean

display is now also available.

By editing the language table, we can put in up to 6

different languages.

The multi-lingual display can help shorten the time needed

for customers to learn the machine operation.

It can also help reduce the chance of operation mistake.

Common Line Deletion(Prevents double cutting),Near Lines cutting

Detection of near lines and overlapping common lines between nearby pieces.

Prevents double cutting, and allows automatic deceleration to avoid damage to adjacent pieces.

Helps shorten the cutting time, and increases the cutting quality and material usage.

Various Parameters

Specific parameters can be set to meet the demand for cutting various kinds of materials.

Optimum cutting setting in accordance to the material

i.e.: Hard car-seat, Knit、industrial use fabrics

Improved acceleration/deceleration,cutting speed

Cutting parameters such as acceleration / deceleration and cutting speed of cutting head can be set with different values for corner, boring etc. Improves cutting accuracy, and reduces cutting time.

Fabric Press (Option)

Mechanism to help hold down the fabrics while moving from

the spreading table onto the cutter.

Prevents fabric slipping, and reduce the manpower needed

to hold down the fabric.

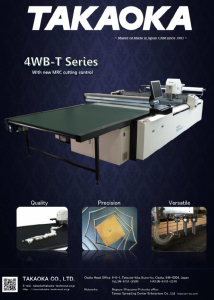

Technocut (Auto cutter CAM) leaflet

Features:

- Drastically upgraded cutting precision for V-notch/Corner/Inner-line cut/Others.

- Greatly boosted Energy saving (Electricity/Air-compression), Low noise, .Productivity.

- High flexibility with customizing service of Cut width, Length, Others devices & Software

for your typical requirement and right solution for your application. - Wide variety of optional tools (Multiple drill, Knife cooler, others…)

- Low cost for maintenance.

<< For Apparel >>

Cotton/Polyester/Salen/Leather/Knit/Wet suit material/Non-woven fabric/Others

<< For Car Seat >>

— Automotive related

Urethane/Elastic material (Stretch)/Leather/Vinyl/Non-woven fabric/Others

— Aircraft related

Glass fiber/Carbon fiber/Ceramic

Catalog

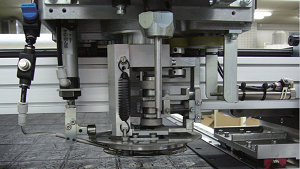

New Cutting Head 4WB |

Traditional Cutting Head 4WB-T |

Video

Option

Option

|

Knife Cooler

|

Multiple drilling system

|

Punch Waste Cleaner

|

Techno Cut Specification

| Specification | TC50 | TC70 | Notes | |

| Feature | Name & Model | Multiply Auto Cutter TC-4WB / TC-4WB-T | ||

| Cutting Width | 1600/1800/2000/2200 mm | |||

| Cutting Length | 2000/2400 mm | Other length is negotiable | ||

| Cutting Height | 50 mm | 70 mm | ||

| Cutting | Suitable Material | Apparel cloth, Car sheet, Industrial material, Non-woven | ||

| Method | Knife reciprocation | |||

| Knives | Width 6 – 8 mm with automatic sharpening system |

|||

| Cutting Speed | Max 40m/Min | |||

| Drill | 1drill, 2 drills, 3 drills, 4 drills, 6 drills | Drill diameter : 1.6mm – 24 mm | ||

| Machine | Knife Head Speed | X/Y a xis Max 40m/min | ||

| Conveyor Speed | 15m/min ( 8m/min during advancing ) |

|||

| Cutting conveyor | Nylon bristles 100mm*100mm | |||

| Vacuum | Vacuum box by blower motor with inverter | |||

| System | Operation PC | Industrial PC | ||

| Data Import | CAD/LAN connection / Cutting schedule software | Can reserve the cut order & parameter in advance |

||

| Languages | English / Japanese | |||

| Power | AC200V (3 phases) | |||

| Others | Compressed Air | 0.6MPa | ||

| Standard Color | Main body : White(KY-875) Head cover : White(KY-875) | Other colors are negotiable | ||

| Machine Weight | 2500 kg ( 1600×2000 ) ~ 3200 kg ( 2000×2400 ) |

|||

| Options | Automatic knife width measure & compensation system, Knife cooler, Punch waste cleaner, travelling system, etc | |||

* Please ask us for more detailed specification

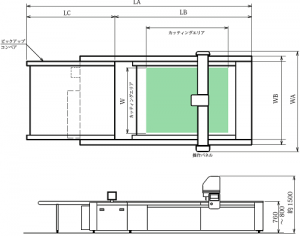

TC50/70 Machine Size

| Width | Length | WA | WB | LA | LB | LC |

| 1600 | 2000 | 2445 | 2170 | 5250 | 3160 | 2090 |

| 1800 | 2000 | 2645 | 2370 | 5250 | 3160 | 2090 |

| 2000 | 2000 | 2845 | 2570 | 5250 | 3160 | 2090 |

| 2200 | 2000 | 3045 | 2770 | 5250 | 3160 | 2090 |

| 1600 | 2400 | 2445 | 2170 | 6050 | 3560 | 2490 |

| 1800 | 2400 | 2645 | 2370 | 6050 | 3560 | 2490 |

| 2000 | 2400 | 2845 | 2570 | 6050 | 3560 | 2490 |

PDF

PDF